Solve It Story: Southern Cloud

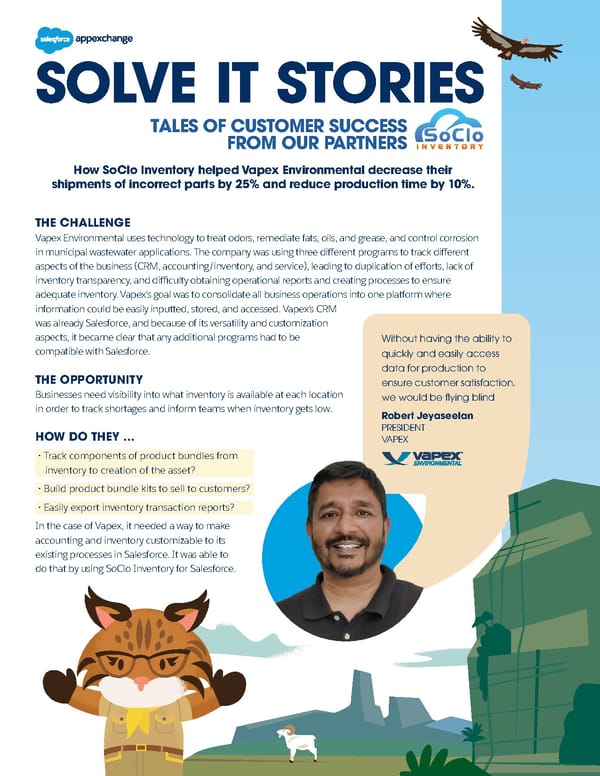

SOLVE IT STORIES TALES OF CUSTOMER SUCCESS FROM OUR PARTNERS How SoClo Inventory helped Vapex Environmental decrease their shipments of incorrect parts by 25% and reduce production time by 10%. THE CHALLENGE Vapex Environmental uses technology to treat odors, remediate fats, oils, and grease, and control corrosion in municipal wastewater applications. The company was using three different programs to track different aspects of the business (CRM, accounting/inventory, and service), leading to duplication of efforts, lack of inventory transparency, and difficulty obtaining operational reports and creating processes to ensure adequate inventory. Vapex’s goal was to consolidate all business operations into one platform where information could be easily inputted, stored, and accessed. Vapex’s CRM was already Salesforce, and because of its versatility and customization aspects, it became clear that any additional programs had to be Without having the ability to compatible with Salesforce. quickly and easily access data for production to THE OPPORTUNITY ensure customer satisfaction, Businesses need visibility into what inventory is available at each location we would be flying blind in order to track shortages and inform teams when inventory gets low. Robert Jeyaseelan HOW DO THEY ... PRESIDENT VAPEX · Track components of product bundles from inventory to creation of the asset? · Build product bundle kits to sell to customers? · Easily export inventory transaction reports? In the case of Vapex, it needed a way to make accounting and inventory customizable to its existing processes in Salesforce. It was able to do that by using SoClo Inventory for Salesforce.

Solve It Story: Southern Cloud Page 2

Solve It Story: Southern Cloud Page 2